For a long time, PK Machinery sticks to the company mission of

“Taking great responsibilities, acting with great morals and making

great achievements”, carries out production and R&D with keen

market insight and rigorous scientific analysis, keeps in step with

the leading standards. We understand the importance of consistency

and reliability, therefore all of our equipment are designed and

built to high standards, from a single machine to a complete

system, PK Machineryalways configures stable System customization

to reach yielding optimum performance.

Headquartered in Xinxiang City.Henan Province,China, domestic

well-known screening and conveying equipment city, PK Machinery has

enjoyed more than 50 steady years of successful growth, and now it

has been widely acknowledged as a trustworthy and professional

manufacturer in the field of bulk material handling equipment,

including vibrating screen, vibrating feeder, belt conveyor, bucket

elevator, screw conveyor, scraper chain conveyor and associated

spare parts in complete specifications.

With series of high sophisticated production equipment, we have set

up the international standard equipment production line, with

production capacity and technological level coming first on the

list. The modern production workshops include screening equipment

workshop, conveying equipment workshop, lifting equipment workshop,

cutting workshop, roller production workshop, the lathe

workshopintegrate machining, fabrication,assembly, and warehouse

all on one,those machinery and workshops are fully performing

international technology standards, production capacity,

technological level.The progressive production equipment is a

microcosm of our strong production strength.

We also understand that our customers’ bulk material screening and

conveying equipment must be operated at peak performance at all

times, that’s why we are whole-heartedly devoted to provide

customers value, achieve maximum efficiency at minimum cost and

obtain the utmost productivity during the sales process. Meanwhile,

PK Machinery is backed up by experienced professionals to provide

guaranteed customer satisfaction, what’s more, one of the most

important aspectsoffered by PK Machinery is the quick and easy

provision of spare parts, in this way, there is no additional

worries for customers once they choose to cooperate with PK

Machinery.

We understand the 21st century is full of openness, with the rapid

and extensive application of high-tech products, the communication

and integration of the world have been accelerated. Since foreign

trade department set up, we have actively expanded overseas

markets. By 2017, our products have been exported to over 140

countries and regions including Russia, UK, USA, France, Germany,

Australia, Malaysia, United Arab Emirates, Indonesia, South Africa,

Iran, Chile, etc. We win highly praise and trust from domestic and

worldwide customers: Baosteel Group, Wiscogroup, Fatima Group, Aker

Solutions, Armstrong Flooring, Tata Group, ATS group, etc., their

trust and long-term cooperation are the motivation to us to pursue

professionalism, innovation, excellence and dedication so as to

indispensable partner.

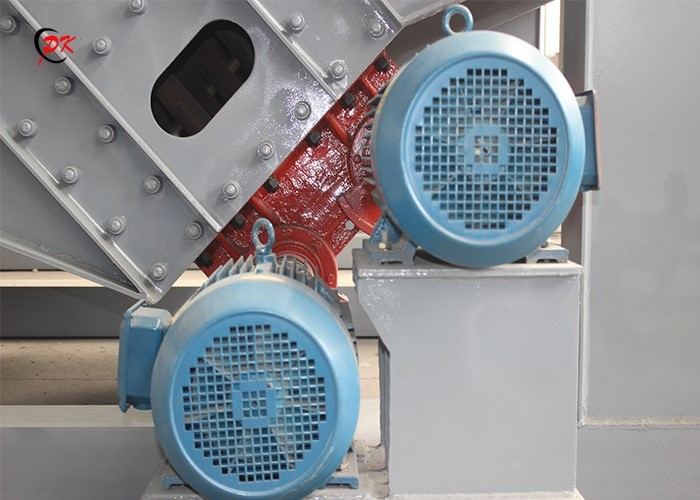

What's more,PK Machinery is always cooperating with the world

famous suppliers with advanced technology, so as to ensure the each

key part of the equipment achieves superior performance, long

service span, little failure and maintenance work. There is also a

important point that once the key part fails, customer can go to

the local agent for free replacement or maintenance, which can save

a lot of time and expense. Motor brand includes: ABB, SEW, WEG,

SIEMENS, ITALVIBRAS; Reducer brand includes: SEW, SIEMENS,FLENDER,

SUMITOMO; Bearing brand includes: NSK, SKF, FAG; Belt brand

includes: CONTITECH, BANDO; Electrical control: SIEMENS, SCHNEIDER.

However, any other brand that is not mentioned, we can customize as

per your specific demand.